Your certified partner for large-engine applications with worldwide know-how

High-speed engines

High-speed engines are used as gensets in CHP plants, in ships, and often in standard containers. As a development partner, HYDAC is on hand to help you and can offer all-inclusive diesel conditioning: from dewatering the day tank to cleaning the fuel in filters located at the engine.

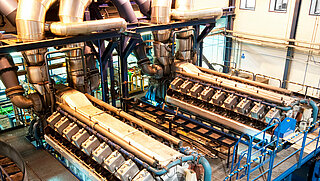

Medium-speed engines

As they can be started up quickly and frequently, medium-speed engines are used in decentralised power plants. The distinctive feature of these engines is their provision of a control reserve. Their high efficiency and low emissions also support the transition to alternative energy. Work with HYDAC to optimise your fuel and lubrication oil systems for efficient and sustainable operation.

Low-speed engines

Low-speed engines provide the energy needed to power large transport ships. For these engines which work according to the 2-stroke principle, fluid conditioning is a key focus. HYDAC takes care of efficient cleaning and dewatering of your operating fluids for reliable and environmentally friendly use under extreme conditions. We can help you to save investment costs and service costs.

Sustainability & standardisation

Never lose sight of efficient and safe operation of your large engine – we work with you to optimise your system and find the custom solution for you. Use the potential of standardisation: retrofitting with optimised components and systems can help you to achieve long-term savings in lubrication oil conditioning and fuel treatment. Contact us today!

Sustainability and standardisation for large engines: our product solutions

HYDAC lubrication oil conditioning in bypass flow

Our system solution sustainably reduces the workload of your main filter and ensures optimised engine protection. Suitable for new systems or as a retrofit solution, our cost-efficient oil conditioning system in the bypass flow does not interfere with your lubrication oil circuit.

HYDAC fuel filter module for multi-fuel engines

With our fuel filter modules, we reliably clean and dewater the fuel of your dual or tri-fuel engine. We achieve the highest level of filtration to extend the service life of your injection system. Find out more today!

HYDAC automatic filter module

Whether it’s continuous flushing or intermittent: our automatic filters clean your fluids efficiently. Benefit from our solutions for all kinds of requirements for the cleanliness class of your fluids. Together we can optimise your engine operation sustainably.

Functional safety

A large engine in decentralised power plants or as a prime mover for ships needs to meet very strict safety requirements. HYDAC is your point of contact for the successful implementation of all statutory safety regulations. Our product solutions focus on SIL-enabled components, SOLAS and IMO requirements and classification regulations, for example.

Functional safety for large engines: our product solutions

HYDAC shut-off device for duplex gas filters

For duplex gas filters, we use double block & bleed technology to clean toxic fuel gases. This makes it possible to perform maintenance work during operation without jeopardising human health or machine condition – 100% availability combined with maximum safety.

HYDAC lubrication oil conditioning

Sustainable conditioning of your lubrication oil thanks to the tried-and-tested Sludge Treatment Unit in conjunction with our automatic filters. Increase both the safety and the availability of your engine and benefit from the time-efficient and cost-efficient HYDAC solution without separators.

HYDAC hydraulic oil cleaning

Your 2-stroke engine hydraulic components are in safe hands with us: our automatic filters ensure that the lubrication oil used meets the strictest cleanliness requirements – to protect your hydraulic systems and guarantee sustainable engine operation.

Balance of Plant

Recognising when action is needed early on calls for coordinated sensors and systems to monitor the condition of your large engines. This enables you to increase the availability and productivity of your system in the long term. For smooth operation of your engine with optimised service and maintenance intervals, HYDAC is your point of contact. With worldwide expertise in the monitoring, analysis and conditioning of your fluids.

Balance of Plant for large engines: our product solutions

HYDAC pressure switches for monitoring filter contamination

Our pressure switches can be used to monitor the contamination of your filters. Custom limits are reliably detected – to protect your system with increased availability and reduced operating costs.

HYDAC sensor for monitoring metallic particles in the lubrication oil circuit

Our Metallic Contamination Sensor detects and classifies metallic wear particles in lubrication oil. Detect damage early on thanks to continuous condition monitoring and prevent unscheduled downtime.

HYDAC sensor module for diesel fuel condition monitoring

HYDAC’s tried-and-tested Contamination Sensor Module is a compact online condition monitoring system for monitoring the condition of diesel fuels. Keep track of the cleanliness of your diesel at all times – prevent loss of efficiency and premature wear in good time.